Circle Track Setup: Springs 101

August 11th, 2014 by Jaime Baker

Ever since the invention of the wheel and its application to mobile carriages, Man has understood the benefits of a proper ride to make travel faster, more efficient, and in general, more pleasurable. Of course, once the second two-wheeled cart was invented, racing was born, and soon the science of suspension was built upon to give way to faster speeds.

Naturally, once the spring was invented, its application to suspending weight was realized, and soon the word “suspension” and its meaning to a chassis was developed. Enthusiasts soon learned that a cart, chariot, or wagon could endure a better, more reliable ride when its weight was set upon springs. This became evident when long travel demanded comfort, which soon led to luxury and style, and eventually to the need for automobiles. Although primitive by modern-day standards, the first car suspensions were designed to do the same thing by the same device: the spring.

Of course, with automobile racing came the need for suspension design and redesign, and eventually, certain truths were applied to a racing chassis. Of these truths, it is most practical to learn the basic truths so that there is meaning behind the numbers, rather than just learning what the numbers “should be.”

Spring Truth #1: Springs are designed to bear weight.

Spring Truth #1: Springs are designed to bear weight.

Seems obvious, right? Well, of course. If you put a weight on a spring, it compresses. Take the weight off, and it decompresses. Where it gets confusing is when you have springs working in unison, and that’s when the spring’s rate (usually in pounds per inch) is critical to know.

If you have a 200 lb/in spring, and you were to place 100 pounds on it, how much does the spring compress? Correct, half an inch. Now let’s say you have two 100 lb/in springs attached by a (weightless) board, and you place 100 pounds on the center of the board. How much does each spring compress? Well, both springs are doing two things:

A: both springs are the same rating.

B: both springs are bearing the weight equally.

In essence, the springs are dividing the 100 pounds between them, and are bearing 50 pounds apiece. Therefore, they are going to compress 1/4″ each.

Easy enough? Okay, let’s complicate things a little.

Same weight, same board, but now let’s use a 25 pound spring and a 50 pound spring. How much does each spring compress?

Since each spring is bearing 50 pounds of weight, the 25 pound spring will compress two inches, and the 50 pound spring will compress one inch.

Now we have a slanted board!

This thought problem, although lengthy, is immensely useful in understanding how the four springs on a race car work with each other. This leads us to another spring truth:

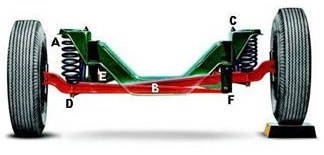

Spring Truth #2: Of the four springs on a car, springs only work together in pairs.

This truth explains why several options are always calculated on a race car for your benefit:

front (nose) weight: weight on both front springs

cross weight: weight on right-front and left-rear springs

left-side weight: weight on both left-side springs

These numbers correlate with certain handling characteristics of a race car, and are very, very important to understand when making adjustments. However, to understand the meaning behind each number, we need to look at why/how they were determined:

Spring Truth #3: Front weight is a measurement of the car’s momentum in a straight line. More front weight = more momentum = push feeling into/out of turns

Spring Truth #4: Cross weight is a measurement of the car’s vulnerability to centripetal forces. More cross = more vulnerable = tighter car

Spring Truth #5: Left side weight is a measurement of the car’s momentum around a turn. More left-side = less momentum = faster turning (just like a pirouetting skater)

These concepts may be confusing now, but in later articles I’m going to show you why thinking about springs in pairs can simplify your understanding of basic car setup, regardless of dirt or asphalt, oval or road.